Maintenance and Service is an important part of owning a Beam Central Vacuum System

Just like your car, a central Vacuum system should have a service to keep it running in tip top condition. Beam recommends that a service of your Central Vacuum system should be undertaken every 2 years. Just check below on what is included in a service of your machine. While Beam is best by test, we do service all the rest!

Beam has a rich history spanning 65 years in the US and 36 years in New Zealand. Beam New Zealand and its Dealers have been successfully servicing Power Units for over three decades. You can have confidence that a Beam Dealer will continue to expertly service your System in the future. For any service required, simply click on 'Find a Dealer' on this website.

When choosing a Beam Central Vacuum System for your home, make sure you receive a copy of your warranty card.

It is important to make sure you keep your Beam system maintained and serviced every 2-3 years.

Our Dealer will discuss Servicing with you, normally they recommend a two year Servicing Schedule.

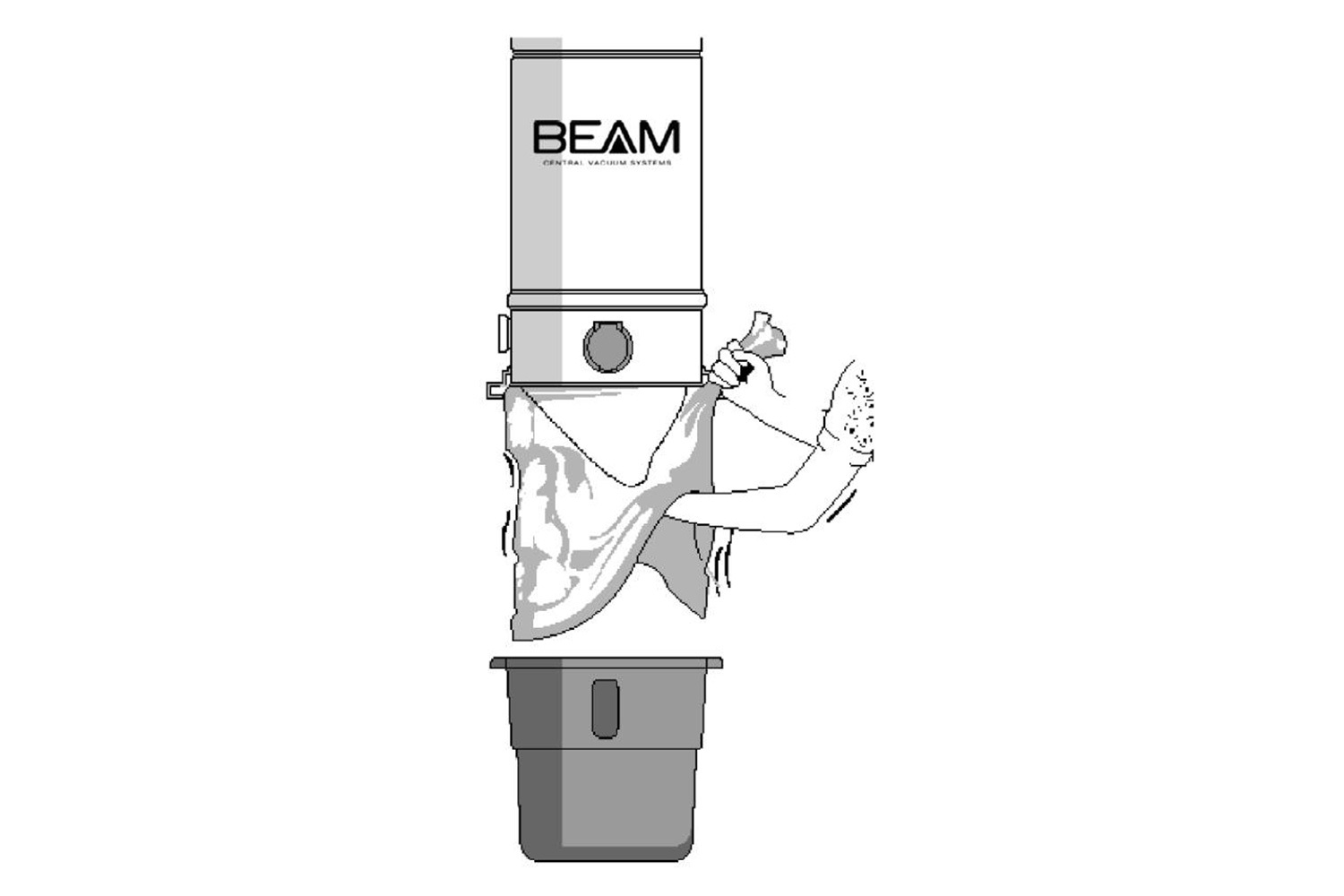

Beam’s patented GORE-TEX, HEPA standard filter is self-cleaning, but still requires maintenance as sharp particles can still damage the GORE fabric. Replacement is recommended every 2-3 years when having your Beam serviced. When cleaning your filter is required just follow these easy steps.

Beam New Zealand recommends that a new GORE -TEX filter is fitted every 2-3 years.

This will ensure that the Beam System will continue to operate at its maximum potential.

An example of how important servicing any Central Vacuum System is for our clients.

The client contacted us asking if we could supply her with a new Beam dusting brush...We said we could, as the conversation progressed, we asked the questions, how old is your machine? has it had been serviced regularly? The client replied, “does it need to be serviced?” “it’s never been done to my knowledge”.

We suggested that a service might be a good idea, saying that a regular service of the system would keep it running at its maximum potential. The client replied “actually, it doesn’t seem to suck as well as it used to”.

Upon initial inspection and vacuum testing of the system, we found that it was down approx 40% in suction as to what it should have been. The motor brushes were just about finished, filter bag was beyond its last legs, all inlet seals were leaking badly and hissing excessively, two of the original wall brackets had split and had broken seals, utility inlet had broken and was loose on the machine, combo floor tool was not working ( even though in good condition ) as it was clogged with years of dirt and the client was using the hard floor tool, on the carpet.

As it turned out, the system hadn’t been touched for many years, it was well beyond its Guarantee, and needed a number of the consumable parts replaced. Our client was over the moon when we ran through our findings with her. The service was completed along with the required maintenance and it was demonstrated to the client that the suction was back to where it should be. She was also very conscious of the health factor of her system (ie removing the exhaust air from the area being vacuumed) and was thrilled that the System was now operating again at the normal level.

Contact us

For over 65 years, BEAM has been a leading manufacturer of central vacuum systems with a long line of innovative products to raise the bar.

Contact us